Automotive Ethernet

KDPOF Presents New KD7051 PHY for Automotive Networking

Cost and Size Reduction by Integrating Transceiver IC, Optoelectronics, and Optics into One Fiber Optic Transceiver

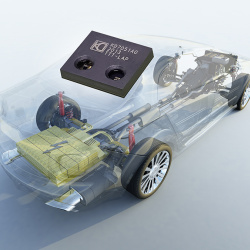

Madrid, Spain, November 18, 2020 – KDPOF, leading supplier for gigabit connectivity over fiber optics, presents the brand new integrated Fiber Optic Transceiver (FOT) KD7051. It is the first device for optical in-vehicle connectivity that incorporates the transceiver IC, optoelectronics, and optics. The integrated FOT is a 100 Mb/s optical port in one single component. “By constructing the ASIC IC, photodiode and LED as one single device, we significantly reduce cost and footprint for automotive Ethernet connectivity at 100 Mb/s,” stated Carlos Pardo, CEO and Co-Founder of KDPOF. “The decreased number of parts also reduces the effort in testing and qualification.” KDPOF’s new KD7051 thus substantially reduces the overall expense compared to STP (shielded twisted pair of copper wires). Further advantages are no margin stacking between links in the supply chain and supply chain simplification. Consequently, it offers competitive pricing for EMC critical or galvanic isolated critical links. Applications include battery management systems, camera and sensor links, fast Ethernet links and smart antenna links.

All New Physical Layer

KDPOF’s new transceiver IC KD7051 offers a complete new FOT design. It reuses low cost MEMs encapsulation and allows SMD reflow assembly with 8 by 7 mm LGA components. The FOT is fully shielded against electromagnetic radiation. Fiber connection is done with a very simple plastic connector placed on top. The temperature range, from -40 °C to +105 °C, conforms with harsh automotive environmental requirements. With a vibration class of V2, it withstands motor conditions. Additionally, the device endures water without sealing. EMC performance is excellent even with the ECU shield case removed, as shielding is integrated into the PCB component. The assembly of the FOT and the IC in the PCB is simplified. Optics implement Tx and Rx lenses. The first prototypes are available.

Simple Implementation

As a plastic optical fiber with a large diameter, POF is more cost-effective to manufacture and install: installation is just easy plug and play; winding and clamping is similar to copper cables. Moreover, during the car assembly, the optical harness can be installed in the same process as the copper harness. POF has been present in vehicles for more than 10 years and is installed in millions of cars.

About KD

Semiconductor supplier KD provides innovative high-speed optical networking solutions for harsh environments. Founded in 2010 in Madrid, Spain, KD offers its cost-effective technology as fully qualified automotive-grade ASSP, integrating electronics, photonics, and optics in a single IC. KD’s technology makes use of information theory, innovative digital adaptive algorithms, and analog mixed-signal design to maximize the receiver’s sensitivity. KD innovates in optical coupling and packaging design, which enables integration of optical communications ports in electronic control units using standard printed circuit assembly processes. Together, these offerings allow KD to support high-yield and reliable optoelectronics production in low-cost automotive-grade bulk CMOS deep submicron nodes, and to deliver products to carmakers with low risk, low cost, and short time-to-market. KD made gigabit communications for step-index plastic optical fiber (SI-POF) a reality for automotive and is now developing its multi-gigabit optimized solution for use with Glass Optical Fiber (GOF) as well.

Related News

- New KD9351 FOT Reduces Cost for Gigabit Connectivity

- Aukua Systems and KDPOF Team up for ISO 21111 Standardization

- Granite River Labs and KDPOF Collaborate to Deliver ISO-Standardized Automotive Ethernet Over POF

- ISO 21111 Complements IEEE Std 802.3bv™ for Overall Standardization of Optical Gigabit Connectivity